You’re running a busy manufacturing business, and every second counts. It’s not an example, it’s your real situation right now. All the time, you feel like you’re facing unique challenges in terms of time, resources, and technology at every step of the manufacturing process.

What if you could harness the power of a tool that not only helps you control your manufacturing operations, but also predicts your needs before problems arise? That’s where Odoo Manufacturing comes in. You can streamline your entire manufacturing process with ease, from your Bills of Materials to real-time inventory tracking and production schedules - all-in-one place with this module.

Are you ready to transform your manufacturing process? Take a moment before answering, and dive deep into our article to really understand the full scope of this valuable function.

5 Common Challenges Of Your Manufacturing Process

Navigating the Malaysian manufacturing landscape comes with many challenges that greatly impact productivity and profitability. These hurdles can complicate the management of a manufacturing business and have a negative impact on operational efficiency, finished product volume, and customer satisfaction.

Escalating Maintenance Costs

As manufacturing scales, the strain on machinery intensifies. For example, high-use equipment such as conveyor systems and CNC machines wear out faster, leading to frequent breakdowns and costly repairs.

This can lead to a spike in maintenance costs, with the need for frequent inspections and emergency repairs. Even if orders double or triple, the financial burden associated with the need for spare parts and specialized maintenance services will weigh heavily on the business owner.

This can be addressed by having internal personnel manually inspect and report to the repair department to avoid production risks. But again, the issue of human resources costs and time will be a headache for you.

Shortage of Skilled Workers

The current labor market situation in Malaysia still shows that the shortage of skilled workers is an urgent problem. In particular, the manufacturing industry faces a double challenge: the younger generation often considers manufacturing jobs less attractive than technology or service industries. At the same time, a significant portion of the current workforce in this industry is about to retire.

According to a report written by The Manufacturing Institute and Deloitte Consulting LLP, about 22% of manufacturing workers will retire in the next decade. The skills gap not only severely hinders production efficiency, but also increases training costs as companies have to spend a lot of time, effort and human resources to upgrade the qualifications of new employees to meet the expertise of innovative production processes.

According to experts, the best solution to this problem is to optimize the workflow, creating a smooth process so that new employees can easily adapt and not feel too tired by applying modern technology.

Complicated Inventory Management

Inventory management is becoming increasingly complex with higher production levels and wider product ranges. For example, a large-scale manufacturer will need to track many raw materials, components and finished products at many locations at the same time.

This complexity will lead to problems of excess inventory in some items, along with shortages in other items, causing delays in production and missed delivery deadlines. More seriously, this will greatly affect customer satisfaction and final revenue.

Inefficient Production Scheduling

Inefficient production scheduling can seriously disrupt manufacturing operations. Outdated or manual scheduling systems may not be able to handle real-time changes in demand or production capacity, leading to inconsistent production and long lead times.

If a factory’s scheduling system cannot automatically adjust to last-minute changes in orders or machine availability, this can lead to problems with scheduling employees (too busy or too idle), and overall workflows can become a mess. Ensuring efficiency can also be a major obstacle.

Rising Operational Overheads

As production volumes increase, so do overall operating costs, related to energy consumption, labor, and materials. Managing these rising costs requires careful budgeting with cost control strategies, such as optimizing energy use, negotiating better prices for raw materials, and streamlining labor costs through process improvements and automation.

Key Features: Check Out What Odoo Manufacturing Can Bring to You

Manufacturing process problems cannot be solved by just modern and powerful machines, but also by an integrated approach capable of managing every aspect of manufacturing.

Odoo Manufacturing modules can help you address key challenges and streamline operations, helping manufacturing businesses in Malaysia improve efficiency and drive growth. Below are detailed:

Product Lifecycle Management (PLM)

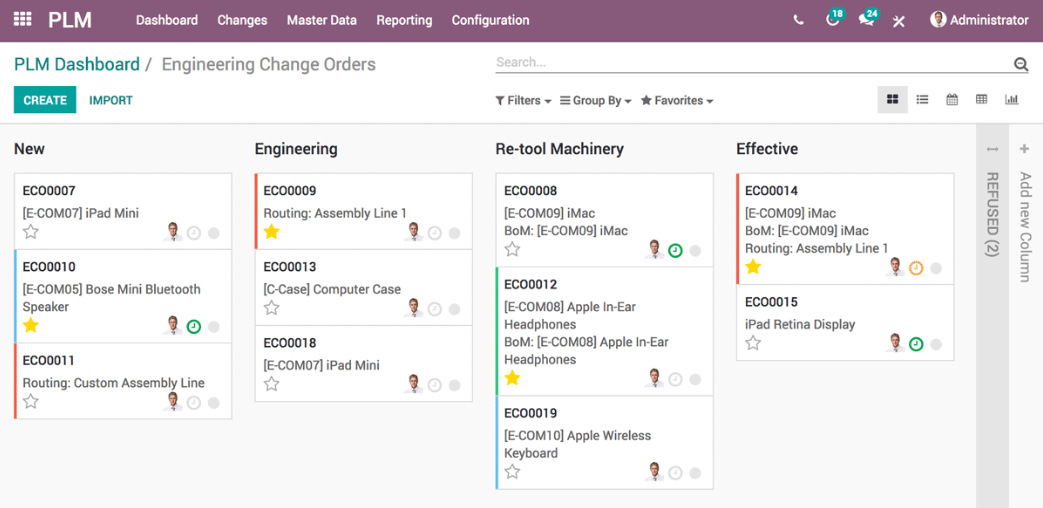

Product Lifecycle Management (PLM) is designed to streamline the entire product lifecycle, from initial concept through production and beyond. It enables manufacturers to manage and track changes efficiently by allowing revisions in Bills of Materials (BOMs) and product designs during various stages of development.

This feature of Odoo for manufacturing also supports the management of Engineering Change Orders (ECOs) and ensures that all revisions are captured and communicated effectively across teams. It improves product quality and reduces time to market, increasing customer satisfaction and touchpoints.

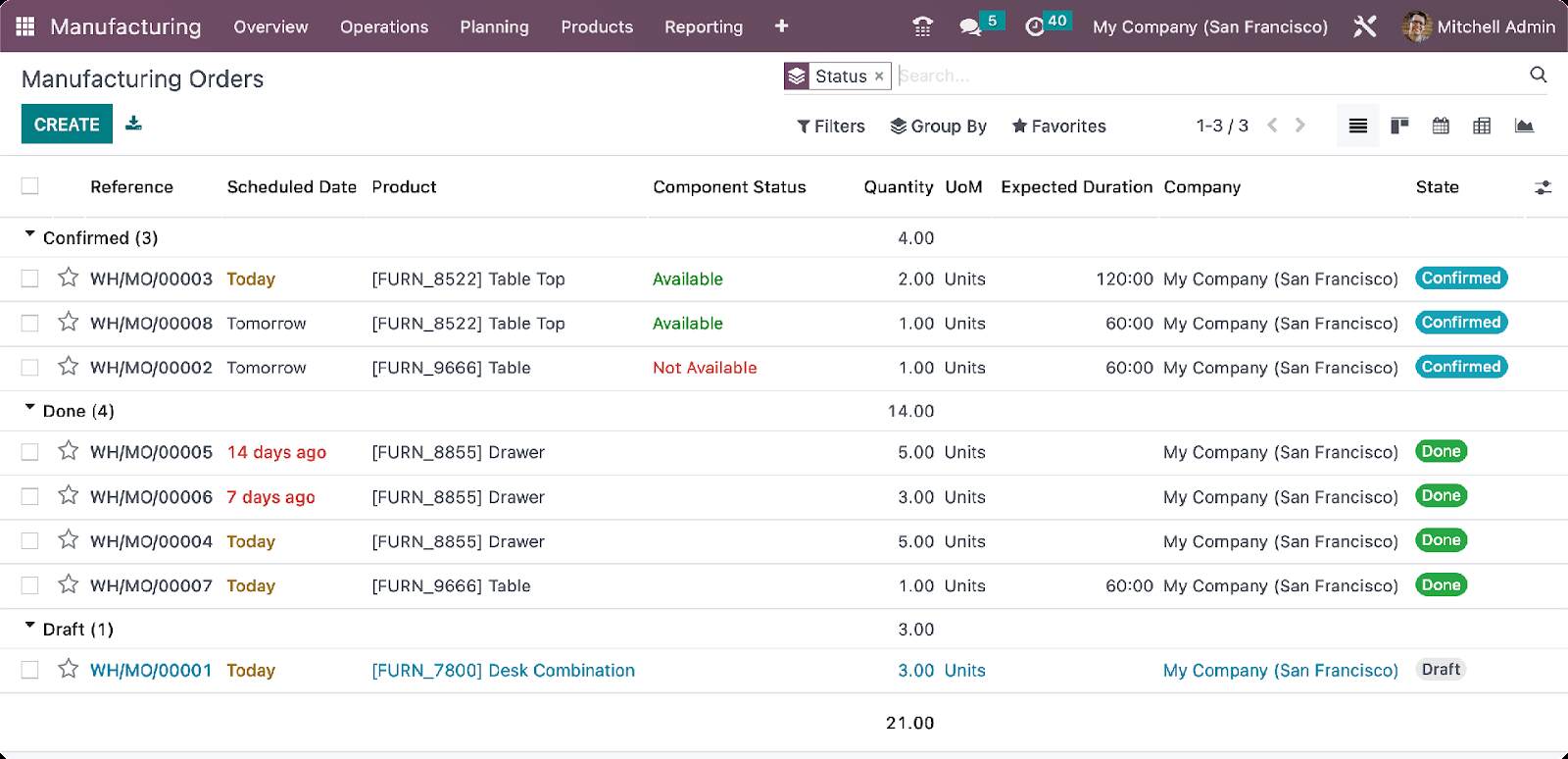

Material Requirements Planning (MRP)

This feature of Odoo MRP helps you optimize production schedules and inventory control. It provides a comprehensive view of material requirements based on current production schedules, as well as forecasts of demand growth in the near future.

By integrating real-time data on inventory levels, production capacity, and lead times, MRP from Odoo for manufacturing helps manufacturers reduce waste and improve schedule accuracy.

Odoo MRP also includes advanced pre-configured tools for planning work at each stage, tracking costs, and managing routes to ensure efficient use of resources and meeting manufacturing goals.

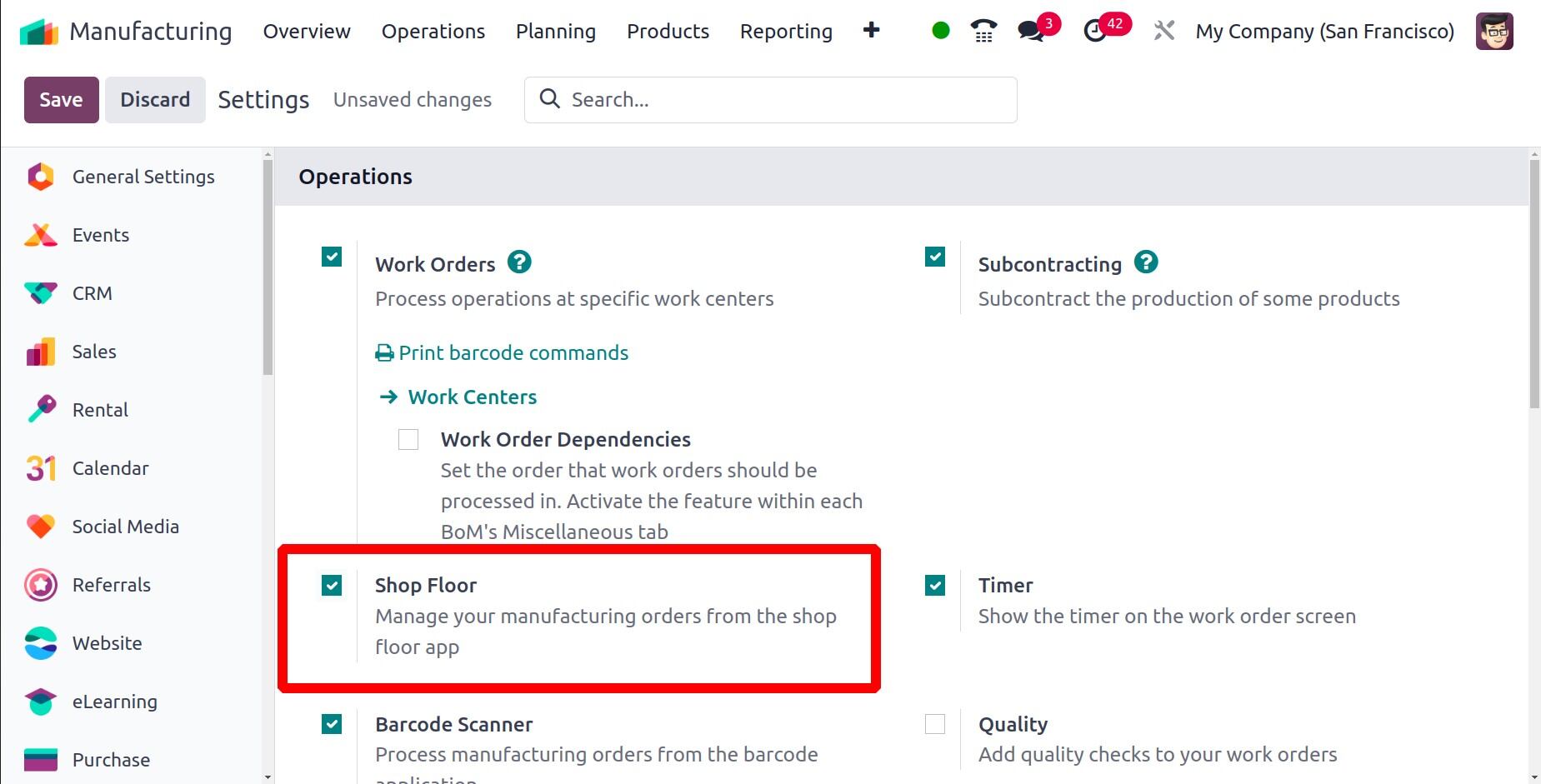

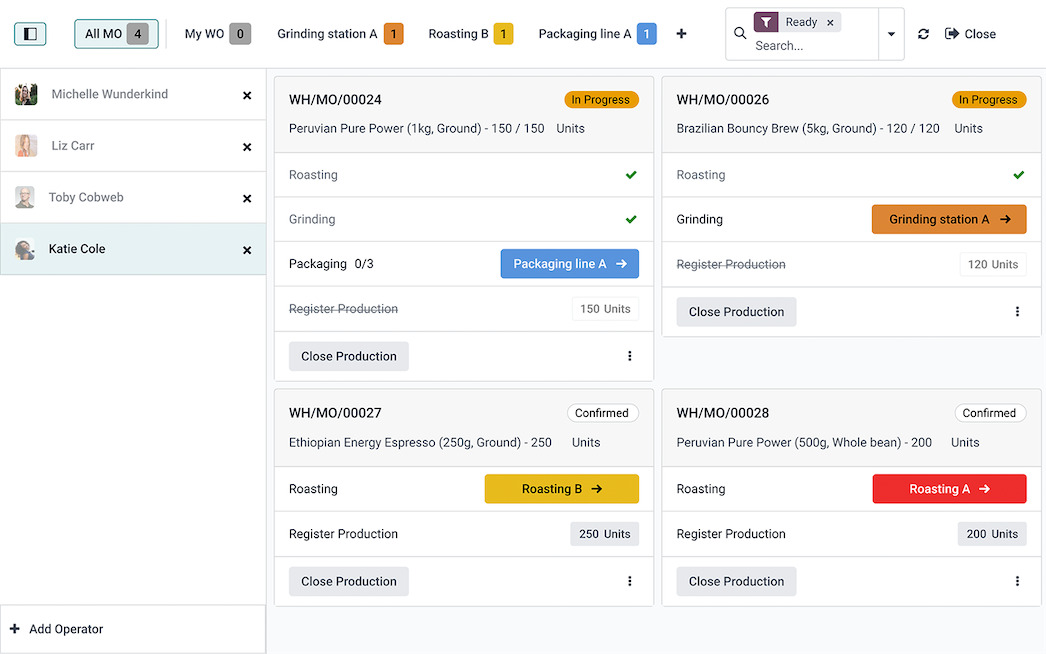

Shop Floor

The shop floor of Odoo Manufacturing increases real-time visibility and control over manufacturing operations. It allows managers to operate and track every work deviation, track time spent on each task, and manage work centers directly from their devices.

This feature from Odoo ERP Manufacturing also supports seamless communication and data collection, making it easy to identify bottlenecks and inefficiencies. Better decision making and keeping the production process running smoothly are also set to become the norm in your work.

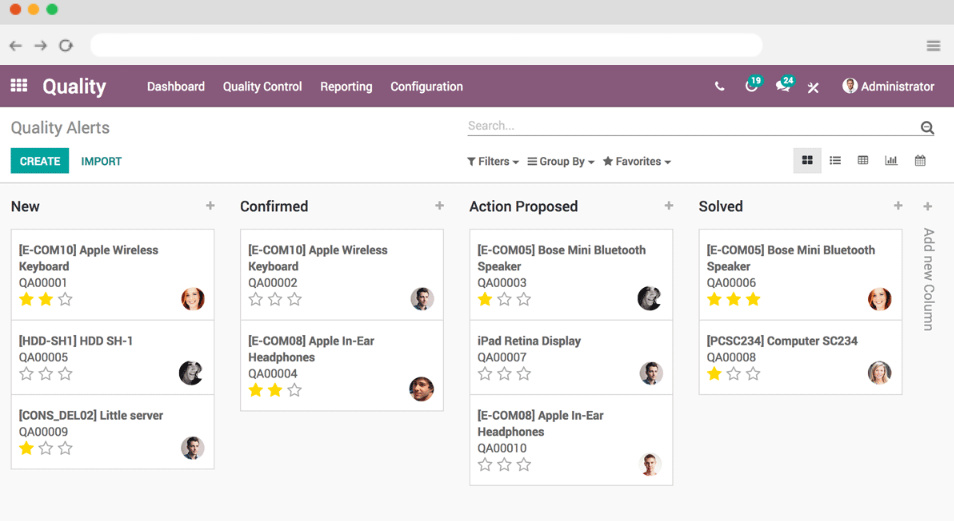

Quality Management

Quality Management of Odoo Manufacturing plays a vital role in maintaining quality standards throughout the manufacturing process. It allows businesses to set up and enforce quality control procedures, with customizable plans and checkpoints at various manufacturing stages.

This feature also automates each quality check, tracks defects closely, and manages corrective actions through Quality Alerts and Worksheets. By integrating quality checks into daily operations rather than waiting for quarterly or annual checks when using Odoo ERP Manufacturing, manufacturers like you can improve product consistency, reduce rework and scrap, and enhance overall customer satisfaction.

Manufacturing Execution Features

The Manufacturing Execution Features (MES) in Odoo Manufacturing are seamlessly integrated with shop floor operations, providing real-time data on production processes. It enables you to control and monitor work orders, track production progress, and perform maintenance tasks.

The MES feature from Odoo for Manufacturing also supports automation through IoT devices, allowing remote control of machines and data collection. This integration helps improve production efficiency, reduce downtime, and ensure that manufacturing processes are executed according to predefined rules and schedules.

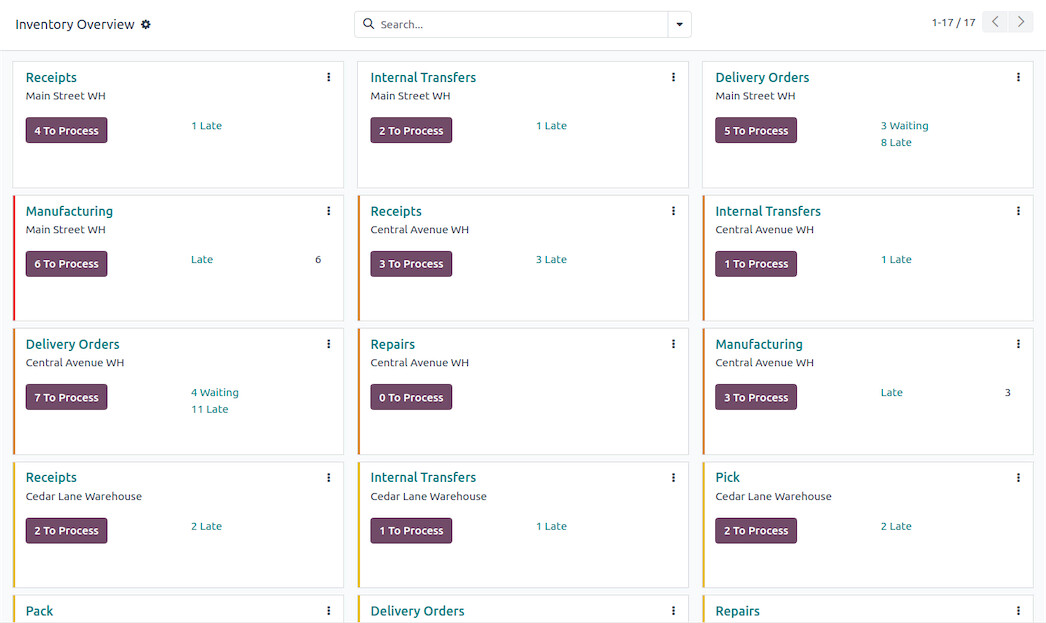

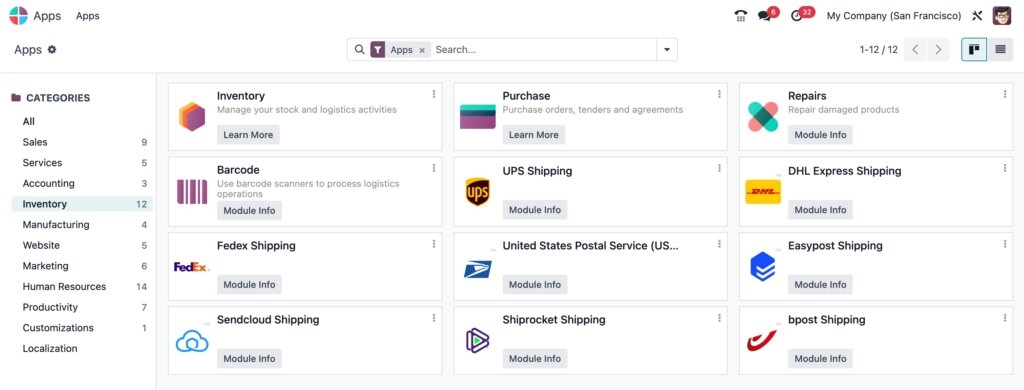

Warehouse and Inventory Management

The Warehouse and Inventory Management capabilities of Odoo Manufacturing module provide powerful tools to optimize inventory control and warehouse operations.

Barcode scanning and real-time tracking of Odoo inventory movements across multiple locations are also present here. It includes functions like Reordering Rules and Automated Replenishment to ensure that inventory levels are maintained efficiently.

At the same time, with capabilities to manage warehouse layouts, define storage hierarchies, and optimize product flows, Odoo for manufacturing helps manufacturers reduce inventory costs and improve operational efficiency.

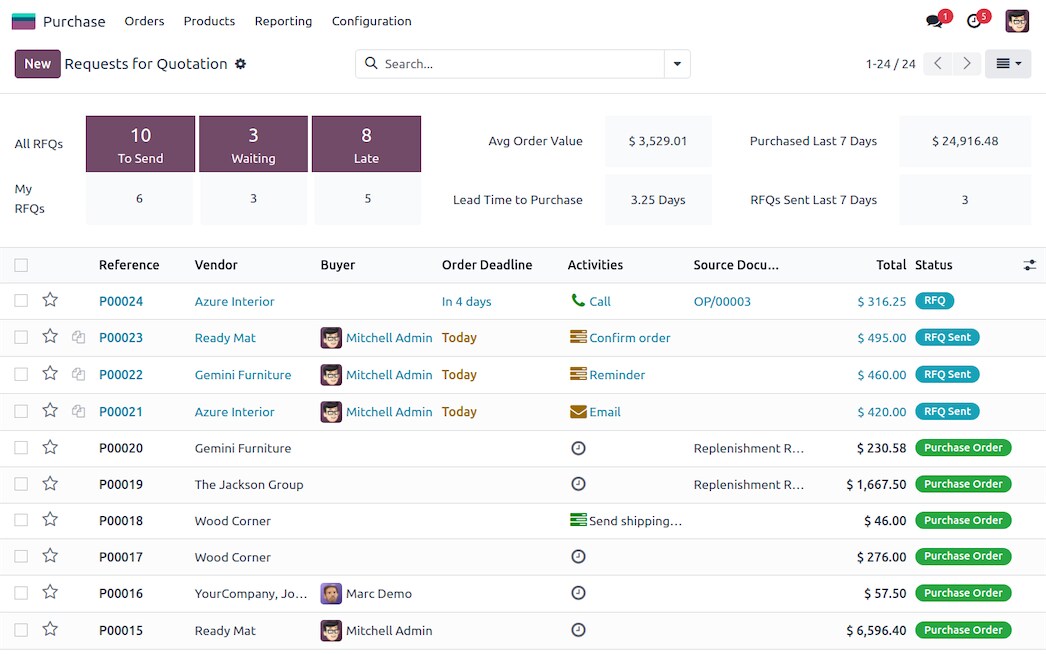

Purchase Management

Purchase Management of Odoo Manufacturing simplifies the procurement process by automating purchase orders, tracking supplier performance, and managing consignment, reducing the need to store excess inventory. This feature also includes dropshipping capabilities, allowing businesses to expand their product offerings without needing additional stock.

Integrating purchase management with inventory and manufacturing data is how Odoo helps businesses improve supply chain efficiency and maintain strong relationships with suppliers.

Supply Chain Journey

Odoo Manufacturing Supply Chain feature facilitates the complete coordination of manufacturing and logistics processes. The system supports advanced routing and logistics management, optimizing the flow of materials and products from suppliers to customers.

Features such as Vendor Consignment and Dropshipping streamline procurement and inventory management, while integration with other modules ensures that supply chain operations are always aligned with production schedules and demand forecasts. This comprehensive approach helps manufacturers improve supply chain visibility, reduce lead times, and increase overall operational flexibility.

You should also read this article: Odoo Accounting Integration: Benefits and Detailed Process

Is Odoo Manufacturing A True Dream In Reality?

Odoo Manufacturing offers a robust set of features that help improve manufacturing efficiency and streamline operations. But of course, there is no advertisement that doesn’t speak well of their products.

How does Odoo Manufacturing fare in real-world use? We have gathered good points and some points needing to be improved from the real feedback and reviews of manufacturers when using Odoo manufacturing.

Pros

- Ease of Use: Odoo Manufacturing has a user-friendly interface with simple functionalities. You can quickly take advantage of the efficiency this feature brings with a simple drag and drop operation.

- Seamless Integration Across Apps: Odoo Manufacturing can seamlessly integrate with other Odoo applications, including CRM, Sales, Inventory, and Accounting. This integration provides a unified approach to managing sales orders, inventory, and manufacturing processes.

- Efficient Item Routing and BoM Integration: Item routing and Bill of Materials (BoM) integration streamlines production planning and inventory management, ensuring efficient tracking and scheduling of orders.

- Robust Quality Management Tools: Odoo Manufacturing’s quality management features, according to users, are extremely robust. It provides tools to create quality controls, manage non-conformances, and analyze quality data efficiently.

- Good Value for the Money: Many users find that the benefits of Odoo Manufacturing outweigh the investment in time, money, and resources. The system's extensive features and support community contribute to the reputation of Odoo ERP solutions as value-added.

Cons

- Customization Challenges and Costs: Odoo Manufacturing offers a wide range of customization options, but the process can be complex and expensive, especially for large enterprises with huge volumes of data. Some users have shared that they have difficulty finding experienced partners and managing the costs associated with customizing the system, which can impact the overall value and effectiveness of the implementation.

- Need for Advanced Analytics: Customers still want to continue to benefit from improved advanced analytics and third-party tool integrations. This will provide deeper insights and improve users’ decision making.

- Limited Built-in Integrations for Tracking Child MOs: Odoo Manufacturing’s integrations lack depth in tracking child MOs (Production Orders). This limitation can impact the ability to effectively manage and monitor complex manufacturing processes.

What’s New For Manufacturing Features in Odoo 18?

Odoo 18, the latest version of Odoo in 2024, is officially available this coming October. There are various new features coming in this version, and Odoo Manufacturing is no exception.

Some details have been revealed by Odoo, promising to make your manufacturing process with Odoo ERP easier than ever. Improving the weaknesses and highlighting the strengths is how Odoo always maintains its position with businesses that record many changes in supply such as the manufacturing field.

Some special key features of Odoo Manufacturing in Odoo 18 are mentioned below:

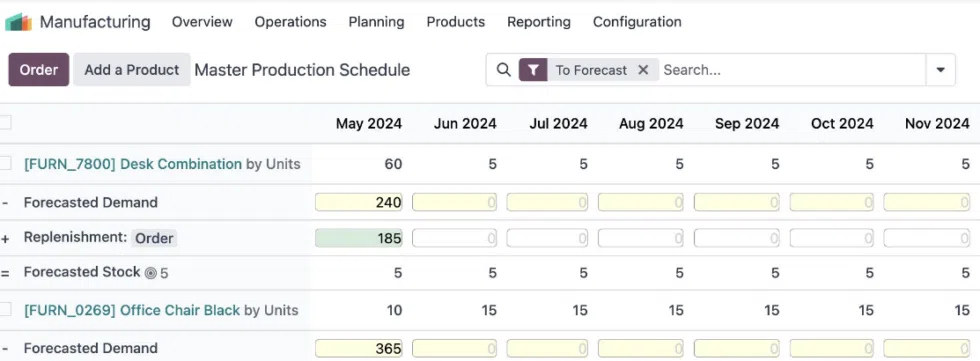

Revamped Master Production Schedule (MPS) UI

Odoo 18 has a newly designed MPS interface that makes production planning and scheduling more intuitive. The user interface has also been updated to include interactive elements such as drag and drop functionality, dynamic charts, allowing users to easily adjust schedules, view real-time data updates, and allocate resources effectively.

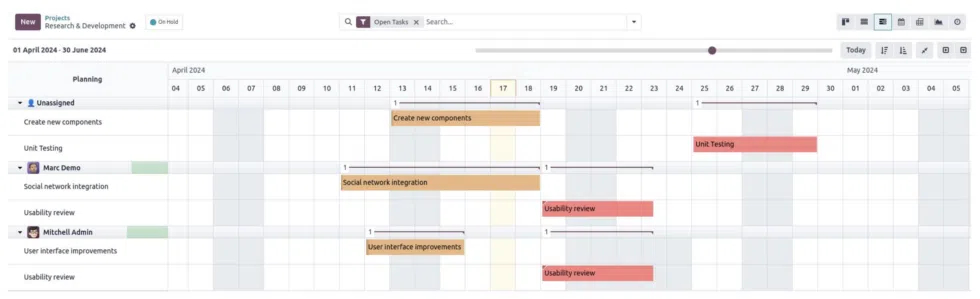

Enhanced Gantt Views

The Gantt views in Manufacturing of Odoo 18 have been upgraded to be easier to use and more visually appealing. Users will be able to zoom in and out, scroll horizontally, and view each task more clearly. These improvements help manage and visualize complex manufacturing schedules easily, improve project tracking, and manage tasks in general.

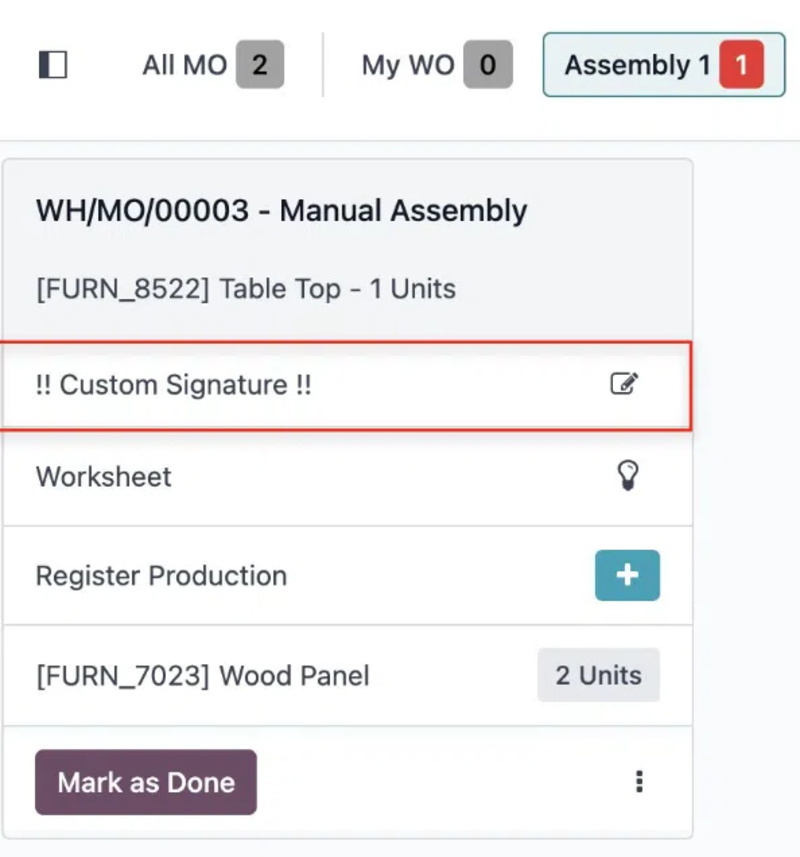

Improved Shop Floor Functionalities

Odoo 18 brings several improvements to the Shop Floor feature, making it more user-friendly. New features include the ability to add notes to assembly tasks, toggle assembly instructions easily, and quickly create new assembly orders with a dedicated button. These updates improve the Shop Floor of Odoo Manufacturing performance and facilitate better task management.

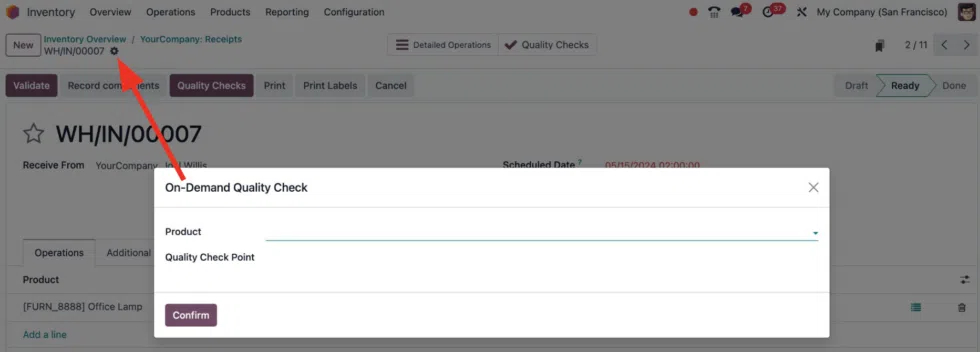

On-Demand Stock Quality Checks

The on-demand quality feature of Odoo Manufacturing in version 18 allows you to perform quality checks directly from stock orders. It streamlines the inventory quality assurance process, reduces the time and effort required to maintain high standards in inventory management, and detects and fixes issues immediately when they arise.

Advanced Planning Tools

The Master Production Schedule (MPS) of Odoo Manufacturing includes advanced planning tools for more accurate demand forecasting and capacity management in Odoo 18. Users can create and compare different manufacturing scenarios, optimize resource utilization, and understand potential bottlenecks to make informed decisions and improve manufacturing efficiency.

Final Thoughts

Odoo Manufacturing plays a role in improving and overcoming the problems that manufacturing businesses are facing. As an all-in-one platform, from creating manufacturing plans to tracking finished products, controlling quality, measuring inventory, Odoo can solve it easily.

This article has provided an overview of the principal features of Odoo Manufacturing, we hope to have conveyed useful and necessary information to you. However, it is certainly not complete or all for you to really understand and make a decision to use Odoo or not. That is why A1 Consulting along with our Odoo solutions are here to help you. With 17+ years of experience in implementing ERP projects for the manufacturing process, our expert teams are always ready to help you and your manufacturing business with custom and advanced consultation about Odoo Manufacturing.

Don’t hesitate to contact us if you have any other questions about Odoo, Odoo Manufacturing features, and also Odoo 18!