Most manufacturers may face challenges in managing production and products because it has quite complex processes. Therefore, it requires effective management of every aspect of the product life cycle closely.

Odoo's Product Lifecycle Management (PLM) module is designed to provide businesses with powerful tools to manage version control and streamline the engineering change process. In this article, we will deeply discover about Odoo PLM from definition, features, benefits and how to use it more effectively to transform your manufacturing operations.

What is Odoo PLM?

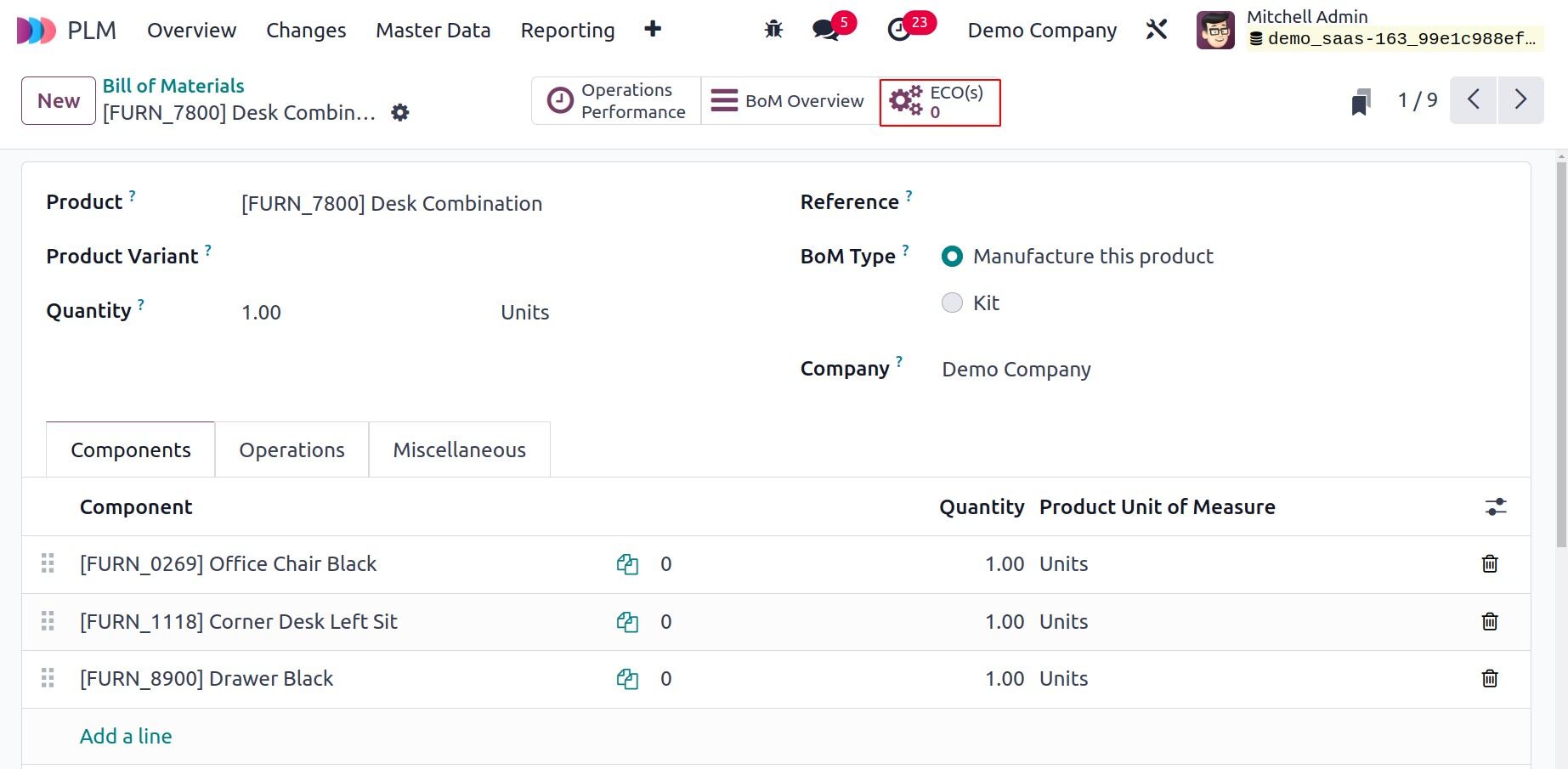

PLM is a product lifecycle management tool, which means managing versions or engineering changes. Odoo PLM can seamlessly integrate with manufacturing and inventory applications to optimize production processes and synchronize data. With Odoo PLM, you can make changes to the bill of materials or manufacturing processes.

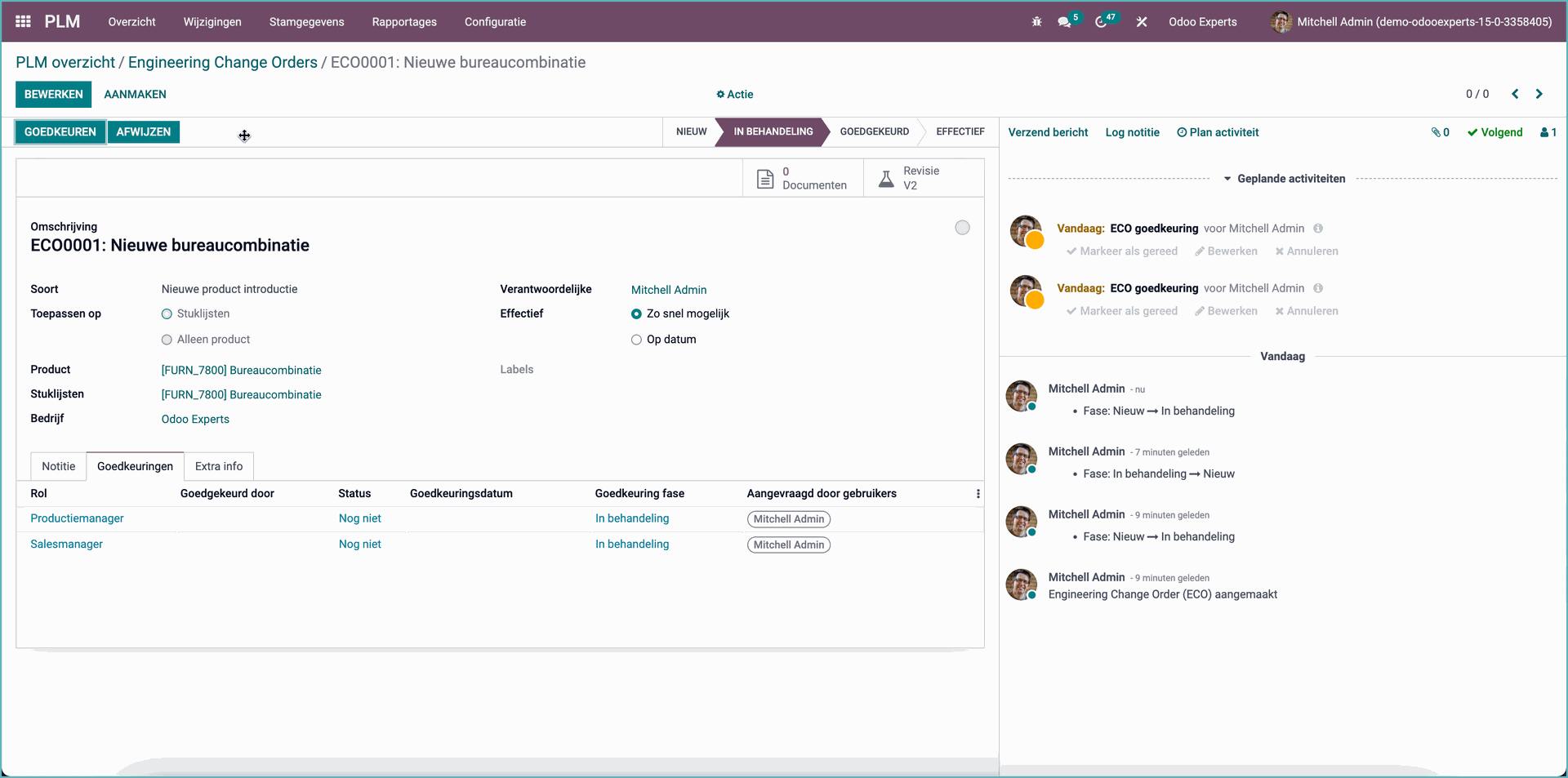

In PLM, you need to know a few terms. An engineering change order (ECO) indicates exactly what has changed in the bill of materials (BoM, Bill Of Materials), whether the quantity has changed, and whether parts have been added or removed. Additionally, ECO also clearly displays the status of the new version, including all the changes.

Thus, it can be said that ECO is known as a document to identify changes and display a list of affected products or parts.

Explore Key Features of Odoo PLM Module

With the manufacturing industry, managing the process plays a vital role in gaining the changes of products or engineering. Leveraging an advanced technology is essential to gain a 360 degree view of changes in this extremely special journey. Let’s browse several main features of Odoo PLM, which aims to unlock its potential.

Navigated Drag-and-Drop Kanban View

Odoo PLM has a user-friendly interface with a drag-and-drop Kanban view. This enables users to easily track and prioritize engineering change orders. In the dashboard, you can get a comprehensive view of tasks, facilitating better planning and execution, which contributes to increased productivity. Additionally, it is easy for a new user to onboard the system and familiarize themselves with the basic features.

Integrated Approvals Workflow

Whether you want to monitor or approve changes, you can do it in the Odoo PLM. It allows you to check, review, and monitor changes in manufacturing easily. You can approve details for specific items on the Bill of Materials (BoM), making sure that every action is carefully reviewed and approved. Furthermore, Odoo PLM has a 360 degree view of changes in BoM so that you can carefully review from changes in operations, BoM changes to BoM iterations without any details being missed.

Multiple BoM Version Management

For products with many variations in size, color or characteristics, managing multiple BoM versions is important. You can create BoM drafts on Odoo PLM which will be stored in the system. Therefore, when utilizing, you can not only seamlessly deploy new versions into production but also easily roll back to previous versions when needed. It is obvious that Odoo PLM is relatively flexible to update the changes so that it benefits a range of products with many variations or need to be updated frequently.

Seamless Integration with Other Odoo Modules

Odoo provides a variety of modules which are useful for businesses in multiple industries to enhance enterprise resourcing. In the manufacturing industry, Odoo PLM integrates seamlessly with other Odoo material applications, including Odoo Manufacturing, Shop Floor, Purchasing, and Inventory. It is certain that the integration of modules makes the manufacturing management process more seamless between different stages from procurement to production and inventory management. As a result, you can easily control all activities in the manufacturing - sale process.

How Surprised: What Makes Odoo PLM Stand Out

With complex and frequently changing products, it is essential to leverage a change management system to ensure everything is thoroughly reviewed, compared, and contrasted. Odoo PLM has useful features for the manufacturing industry to manage the entire product lifecycle. Here are several benefits of Odoo PLM you need to know:

- Enhanced Collaboration: Odoo offers power communication tools which promote collaboration between team members. They can interact and share documents in a centralized platform to manage technical changes and approvals.

- Improved Accuracy: Odoo PLM provides powerful approval integration capabilities so that you can track comprehensive product and manufacturing process details. Make sure that every change is recorded and executed accurately, which aims to minimize the risk of errors.

- Greater Flexibility: As mentioned above, Odoo PLM is capable of managing multiple BoM versions, which is suitable for complex and multi-component products. Businesses can track and respond to changing market demands and product upgrades allowing businesses to quickly adapt to market demands and product innovation.

- Efficiency Boost: Odoo PLM offers intuitive Kanban views and seamless integration with other Odoo modules, which helps streamline processes as well as save time and resources. You don't need to manage data across multiple systems.

You should also read this article: Potential of Odoo eCommerce: Definition, Benefits, and How to Use

How to Use Odoo PLM Effectively: 10 Big Steps for You

Odoo PLM brings many benefits for the manufacturing industry, which supports improving the lifecycle management of products. To utilize Odoo PLM optimally, we show you a step-by-step guide to use the PLM module. Let’s see:

Step 1: Configure Odoo PLM Module

First of all, you need to install the PLM (Product Life Cycle Management) Module in the Database. Odoo PLM is specially designed for engineering departments and is used to handle changes in the bill of material (BoM) and track material life cycles based on engineering change orders (ECO).

Step 2: Take an Overview

Once the module is installed. You can see the overview during startup. When seeing the Count of ECO lifecycle, you can click Overview in the menu bar of the PLM Module.

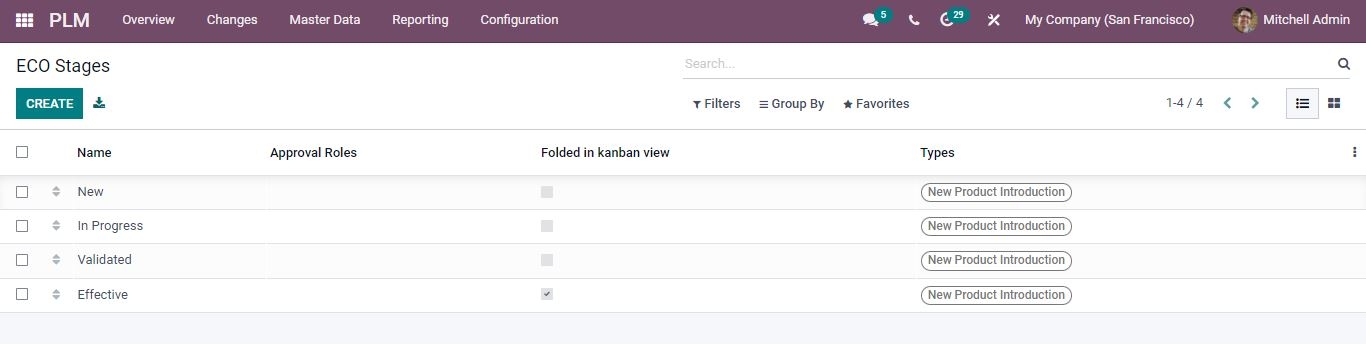

Step 3: Define ECO

Start the new research for ECO by putting together a briefing with someone who has responsibility and product for the engineering department. Here we can add more steps of type ECO by adding color. This is similar to the CRM and Project modules in Odoo. However, in this case, according to the policy, an optional consent may be added for each party. We discuss this in a later section.

In this phase, we can notice the four phases namely New, In Progress, Approval, and Effective in ECO(Engineering Change Orders).

- New: This field indicates that we are creating new ECOs (Engineering Change Orders).

- In progress: This field displays when Engineering Change Orders(ECO) are in effect.

- Approvals: This field is used to set the approval of changes to the appropriate authorities in the hierarchy administrator role. Consent for platforms can be set in platform settings. Authorities and approvals can be added here.

- Effective: This field is used only when the ECO is highlighted. Now we can use the checkboxes, which allow us to use changes and final stages and fold them in Kanban view. This part will be marked as the last step.

Step 4: Create ECO

You can now access the PLM dashboard and trigger the Engineering Change Order. You can fill in the following required fields. To create an ECO (Engineering Change Order) go to the PLM dashboard and click the Engineering Change button for the ECO. Define a brief summary of the changes and upload BoM or Routing OR an item we can choose as needed.

Now you can select the ECO type. The Effectivity field is used to specify the date when the change should be applied. After filling in all the required fields and saving the changes. Click Start Revision Button then.

Step 5: Manage BOM Versions

You now have further amendments to the Bill of Material, such as an Engineering Change Order (ECO) to initiate work on new BOMs. Note that you need to fill in the correct changes without disturbing BoM versions. Here you can upload any other CAD or Document to the relevant ECO.

Step 6: Change/ Edit BOM

Then edit the Bill of Material (BoM) and add attachments whenever required. All your changes will be updated automatically and saved as drafts. At that time you can add two items and all changes made are again reflected in Engineering Change orders (ECO).

Step 7: Check and Reflect

Once two components have been added and the quantity of the existing component has been updated. After that, all modifications will be displayed in the ECO under the BoM changes tab.

Step 8: Approve ECO

ECO is now moved from the In Progress stage to the Approval stage by drag and drop. At that time, we may appoint an administrator to approve the change. The Kanban view of ECO allows the Assigned Administrator to search and define Stages by drag and Drop of ECO after Approval. At the same time, we can move from the Approval stage to the Effective stage by drag and drop.

Step 9: Come to Effective Stage

The effective part is the last part. Now we can easily drag the ECO to the Effective stage like the last stage and apply the same changes and then apply the changes.

Step 10: Finalize The Journey

Finally, you can see all BoM Versions of Manage by Engineering department users. It is certain that you can customize the BoM or choose the BoM version you want because they are recorded as drafts.

Conclusion

Effective PLM has become essential for the manufacturing industry. Odoo PLM provides the tools needed to manage technological change and streamline product development, help businesses optimize productivity, improve cross-functional collaboration, and ensure consistency at every business step This also allows manufacturers to quickly adapt to market demands while maintaining high quality.

Looking for a good solution to manage the life cycle of products, or any custom Odoo services consultation? Contact us today!